Antminer APW7 Power Supply Repair Guide

Version date: 2019.8.4

File Category: Maintenance Plan

Content of this Volume: It mainly describes the troubleshooting of various faults of the power supply APW7, and how to use the test tool for accurate positioning.

※ The copyright of this article belongs to Bitmaintech Pte.Ltd (Bitmain). The article shall solely be reprinted, extracted or used in any other ways with the permission of the copyright owner. Please contact Bitmain official customer service if there is any need of reprinting or quoting.

I. Requirements on the Maintenance Platform

1. The constant temperature soldering iron above 80W (soldering temperature: 300-350°C). The tip soldering iron head is used for soldering chip resistors and capacitors. The blade type soldering iron head is used for soldering and replacement of plug-in components (soldering temperature: 380-420°C)

2. The thermal chimney is used for chip disassembly and soldering, be careful not to heat for a long time to avoid PCB foaming (soldering temperature: 260°C ±2 °C).

3. The AC controllable power supply voltage regulator (output 200 250V, can limit 0-20A current) is used for APW7 power-on inspection. If there is no such condition, a 100W ordinary light bulb can also be strung on the AC fire line with mains. Power analyzer used for PF value and power calculation test after power supply repair.

4. For electronic load (power 2KW, meet the voltage 0-50V), if there is no such condition, a resistive load that matches the APW7 can also be made.

5. The Fluke 15b+ multimeter, suction gun, tweezers, test station surface has electrostatic protection (if there is condition, an oscilloscope can be configured).

6. Flux, lead-free tin wire, water for cleaning panel with anhydrous alcohol; water for cleaning panel is used to clean flux residue and appearance after maintenance.

7. Thermally conductive silicone grease (2500) is used to repair the thermal conduction between the MOS and the cooling fin, thermal conductive silicone (704 silica gel) is used for fixing and covering the glue damage at the original after the repair ofthe PCBA components.

II. Requirements on Maintenance Operations

1. The maintenance personnel must have certain electronic knowledge, more than one year of maintenance experience, and a certain understanding of the working principle of switching power supply, and well master the soldering technology.

2. Before the product is opened and the PCBA panel is repaired, the large capacitor must be discharged, and the voltage must be measured with a multimeter (less than 5V discharge), and then the soldering operation can be performed! Be sure to confirm to avoid electric shock.

3. Pay attention to the working method when judging the circuit components. After replacing any device, the PCB panel has no obvious deformation, the soldering of bonding pad is reliable, and the replacement parts and the surrounding area have no problem such as insufficient parts, open circuit or short circuit.

4. After replacing the key components, the main circuit shall have no short circuit and other obvious abnormalities before the AC voltage test, otherwise there is a hidden danger of explosion.

5. It needs AC220V voltage to judge the circuit signal; pay attention to operational protection.

The following: Notes, key slogans

● Maintenance personnel qualifications must meet the specified requirements;

● Instruments and equipment used for maintenance must meet the specified requirements;

● The instruments and equipment for maintenance must be effectively grounded, and the maintenance environment must comply with anti-static requirements; Of course, it is better to wear an anti-static wrist strap during maintenance.

● Materials used for maintenance must meet the specified requirements; in order to guarantee the accuracy and traceability of the materials used for maintenance, the materials used for maintenance must be the production materials for the corresponding models, and the material replacement must be confirmed;

Notice:

1. In order to prevent possible electric shock hazard, non professionals should not disassemble the enclosur;

2. The maintenance personnel shall use a special enclosure opener to open the enclosure of the power adapter and repair, to avoid damage to the internal components of the product;

3. After the product is opened, it is required to discharge the high voltage capacitor;

4. E-waste waste generated during product maintenance cannot be arbitrarily dropped;

5. Bad products must have a repair process card and indicate the cause of the failure, and placed separately;

6. The repaired products must be well marked to distinguish;

7. The repaired products must be placed in the repaired area and shall be systematically tested before they can be stored.

1. Principle overview

1.1 APW7 performance characteristics and scope of use

APW7 - 12- 1800 series power supply is a high-efficiency DC power supply designed and produced by our company, with single-phase AC input, single DC 12V output, and can meet the common DC load of 12V 1800W, especially suitable for circumstances with strict requirements for power supply of servers and miners; it has the following characteristics:

◆ 200-264V voltage input, power factor greater than 0.99 (full load);

◆ Maximum conversion efficiency up to 95% (without output line loss);

◆ Output ripple less than 1%;

◆ Undervoltage, short circuit, overload, over temperature protection, automatic recovery after fault removal;

◆ The use of high-quality devices ensures stable and reliable products through reasonable design, and can work at full load for a long time in a high temperature environment at 60°C or lower;

◆ Small size and high power and density.

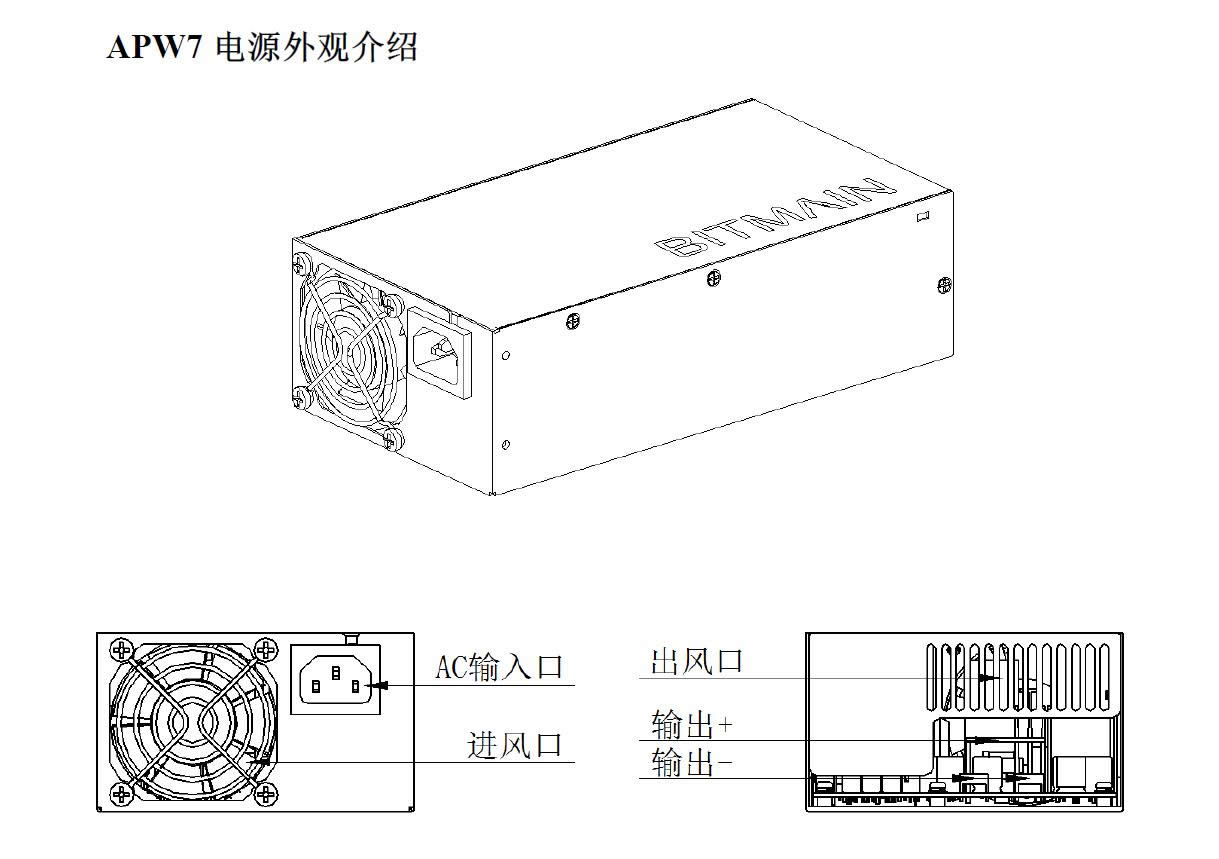

1.2 Appearance of APW7 Power Supply

APW7 电源外观介绍: Appearance of APW7 power supply

AC 输入口: AC input port

出风口: Air outlet

进风口: Air inlet

输出+:Output +

输出- :Output -

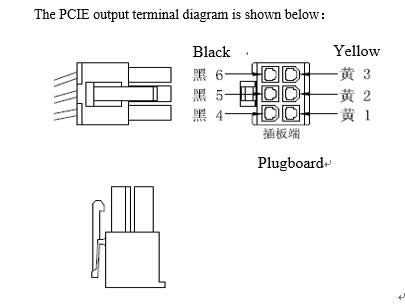

The model of the AC input terminal on the power supply front panel is C14, and the AC input cable of the C13 interface is required. The power supply is equipped with an output line. The standard model output line contains a total of 10 PCI-E output terminals with a line length of 380mm. Other output lines can be customized according to the actual needs of the customer. The PCI-E output terminal diagram is as follows:

The output line consists of two color lines, the 12V positive line is yellow, and the negative line is black. Definition of 6PIN PCI-E terminal positive and negative poles:

Positive pole: yellow 1, yellow 2, yellow 3

Negative pole: black 4, black 5, black 6

1.21 The are following characteristics:

200-240V voltage input;

There is protection for undervoltage, short circuit, overload, over temperature, with automatic recovery after fault removal;

The use of high-quality devices ensures stable and reliable products through reasonable design, and can work at full load for a temperature environment at 60°C or lower;

Small size, high power density.

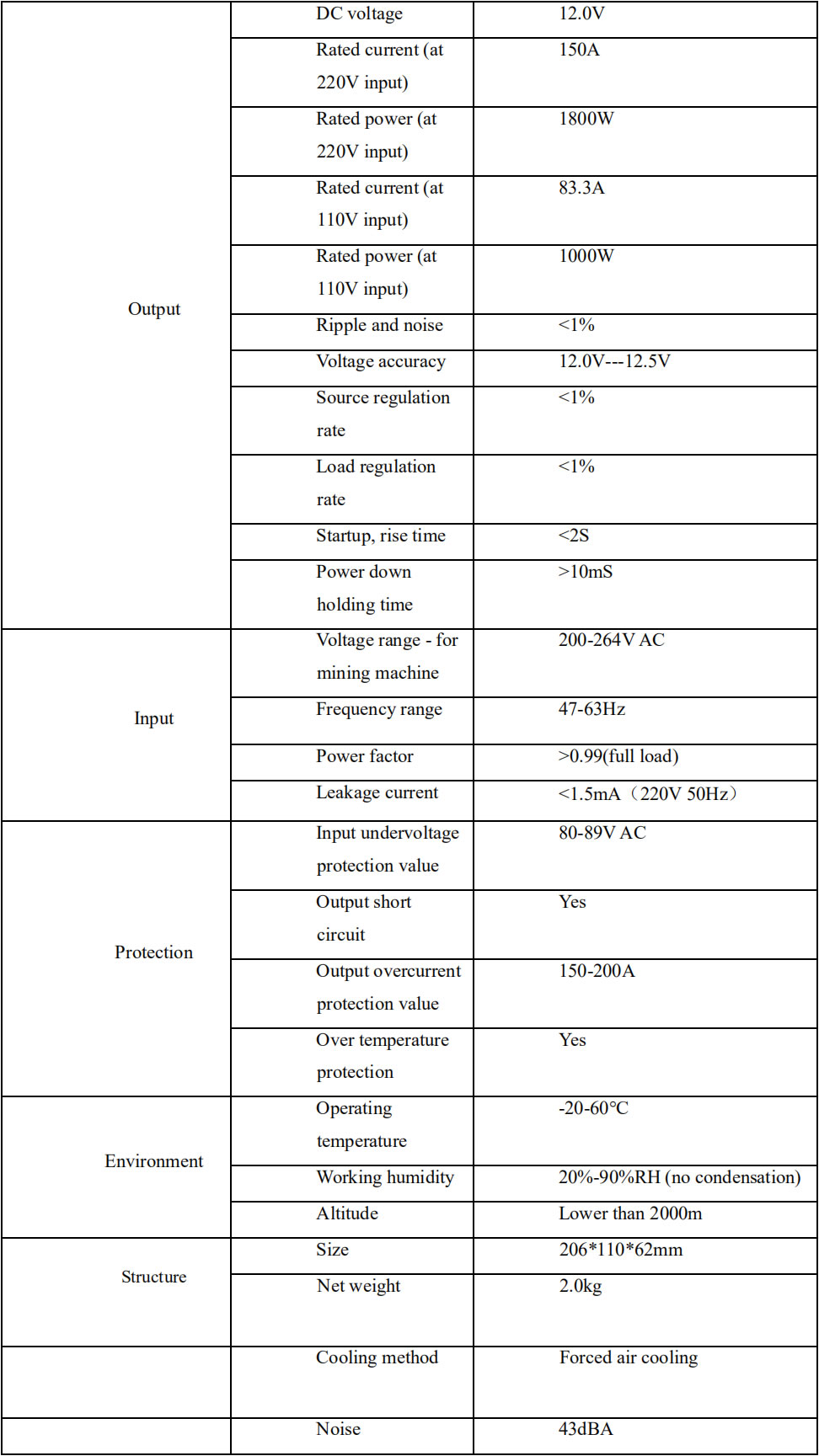

1.3 Parameters of APW7 Power Supply:

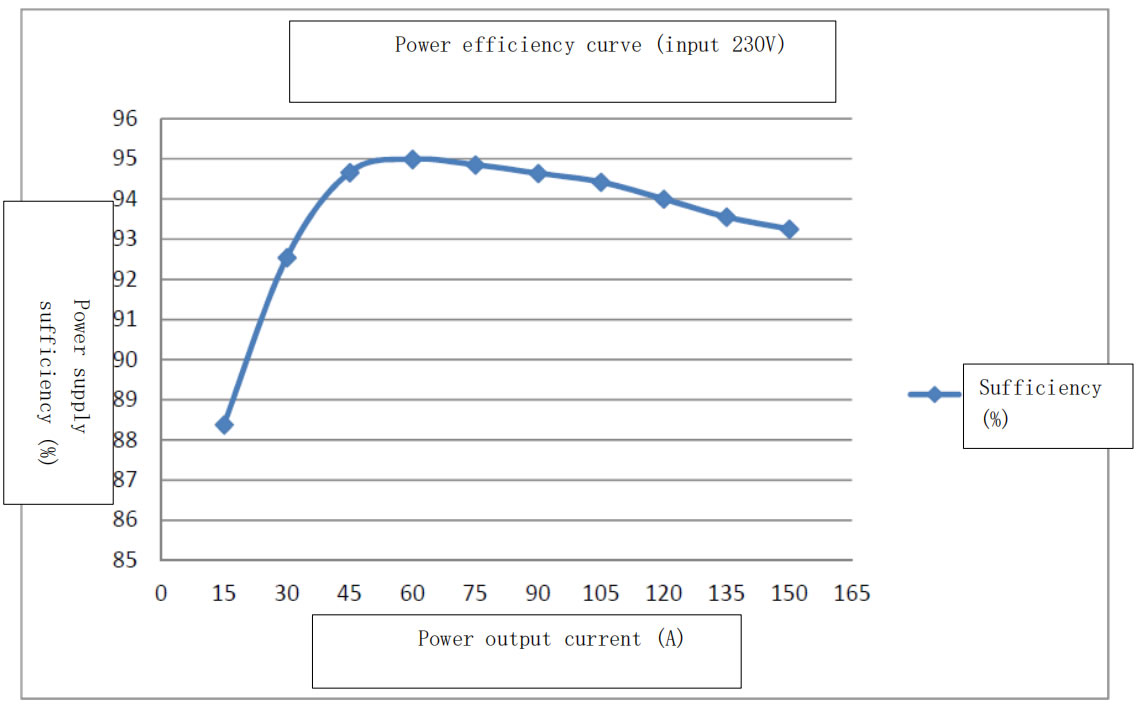

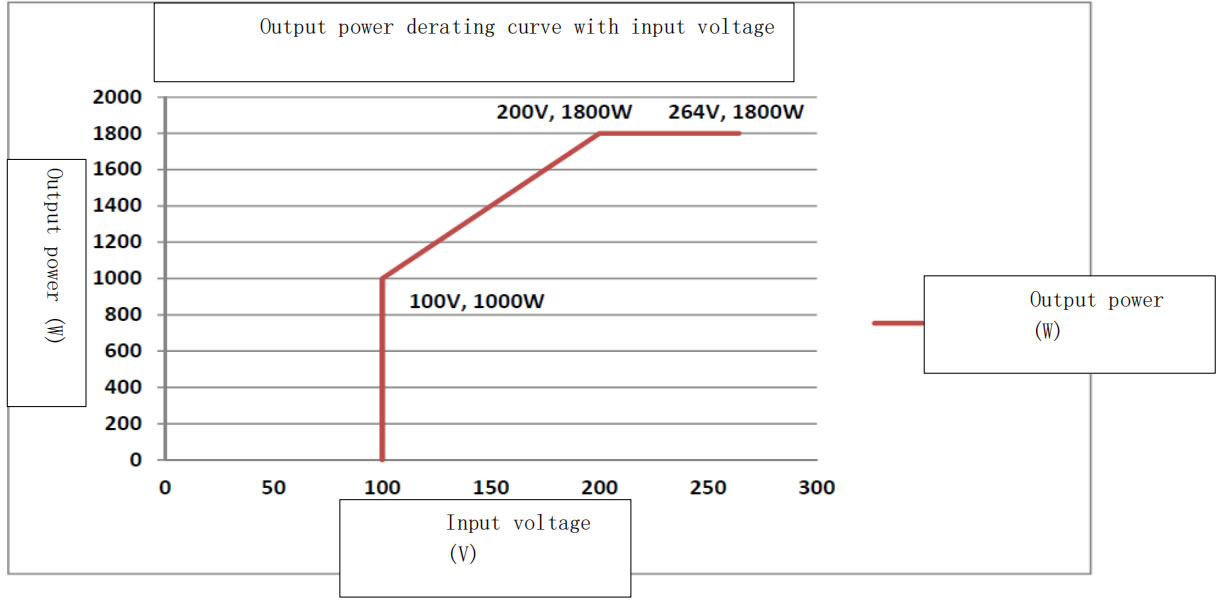

1.4 Voltage efficiency ratio:

APW7 efficiency curve (excluding output line loss)

APW7 output power with input voltage derating curve

2. Maintenance ideas and cases of common faults

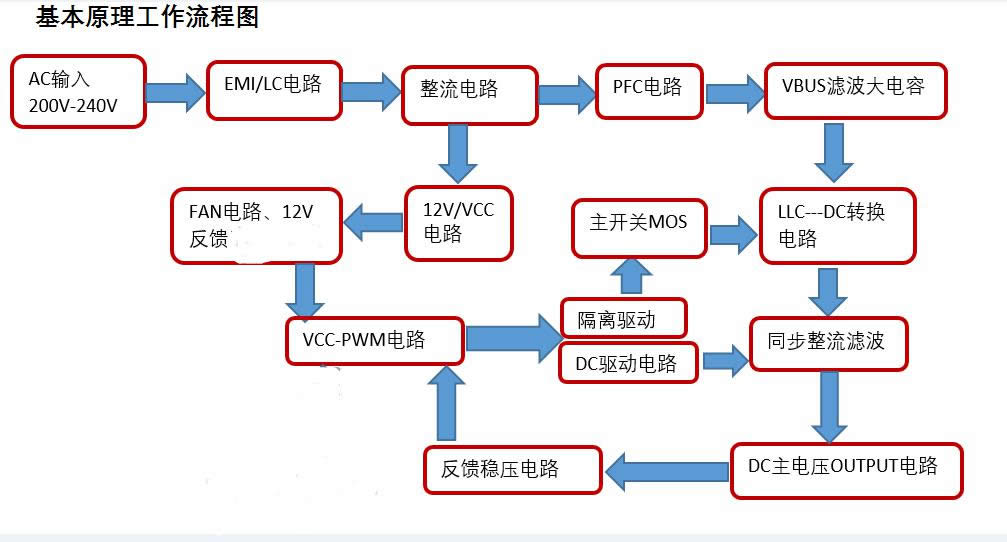

2.1 Block diagram for power basic principle

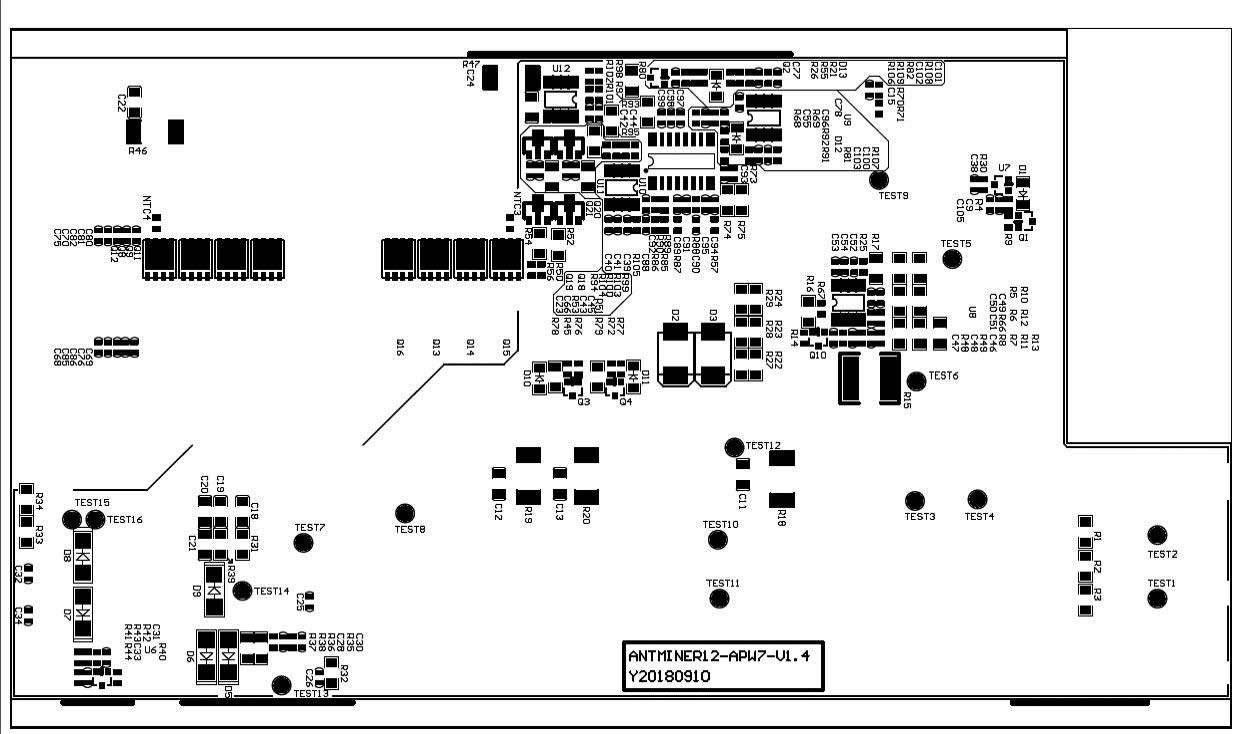

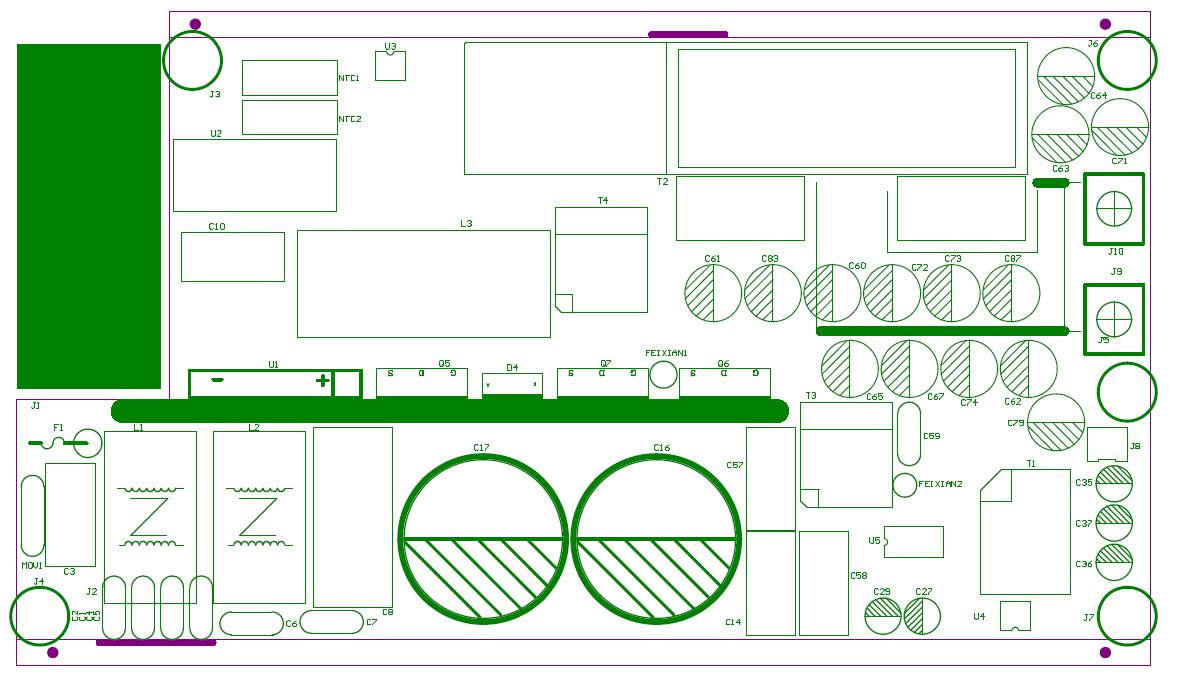

2.2 Power PCBA board layout

1. Input F1 fuse

2. Rectifier bridge PFC drive and main Q circuit

3. LLC main switch circuit

4. Auxiliary power circuit provides VCC power supply

5. PWM drive and detection feedback protection circuit

6. The main output circuit rectifier MOS

Physical picture of DIP plug-in(there will be small differences in product versions, but the structure is the same)

继电器、 NTC 电阻: Relay, NTC resistor

主变压器: Main transformer

整流桥、 PFC 、MOS、电感: Rectifier bridge, PFC, MOS, inductance

PWM 主 MOS: PWM main MOS

12V 主输出: 12V main output

AC 输入: AC input

VBUS 大电容: VBUS large capacitor

12V,VCC,FAN 电器:12V, VCC, FAN appliances

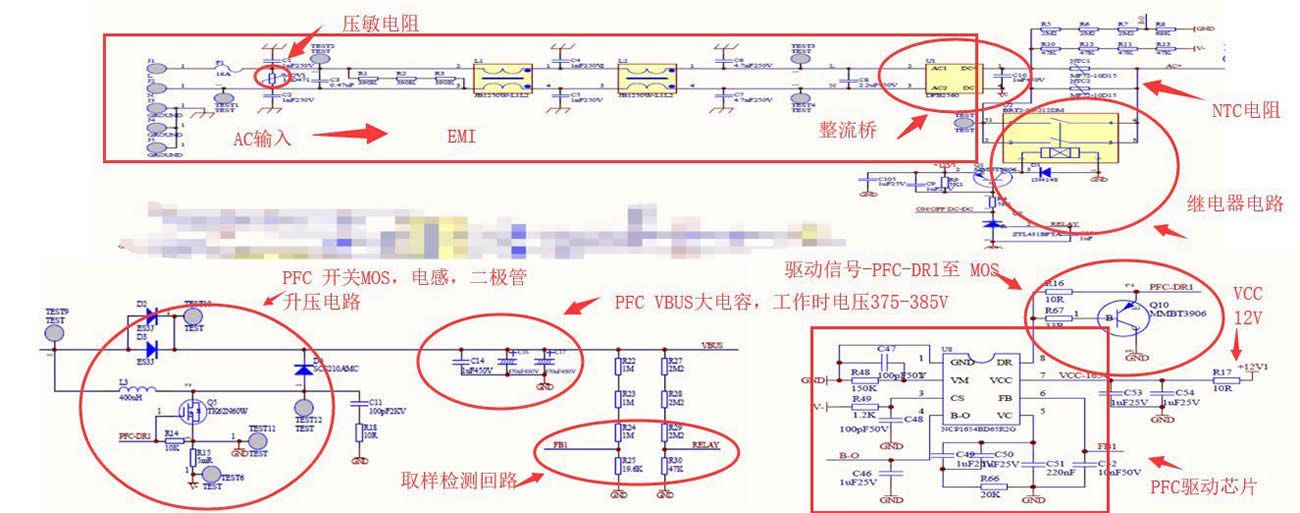

2.21 AC inputs EMI to PFC circuit schematic, focus on measuring whether F1 insurance, U2 rectifier bridge, Q4, D7, D5, D6 are damaged.

压敏电阻: Varistor

AC 输入: AC input

整流桥: Rectifier bridge

NTC 电阻: NTC resistor

继电器电路: Relay circuit

PFC 开关 MOS,电感、二极管升压电路: PFC switch MOS, inductance, diode boost circuit

PFC VBUS 大电容, 工作时电压 375-385V: PFC VBUS large capacitor, working voltage 375-385V

取样检测回路: Sampling detection circuit

驱动信号-PFC-DRI 至 MOS: Drive signal - PFC-DRI to MOS

PFC 驱动芯片: PFC driver chip

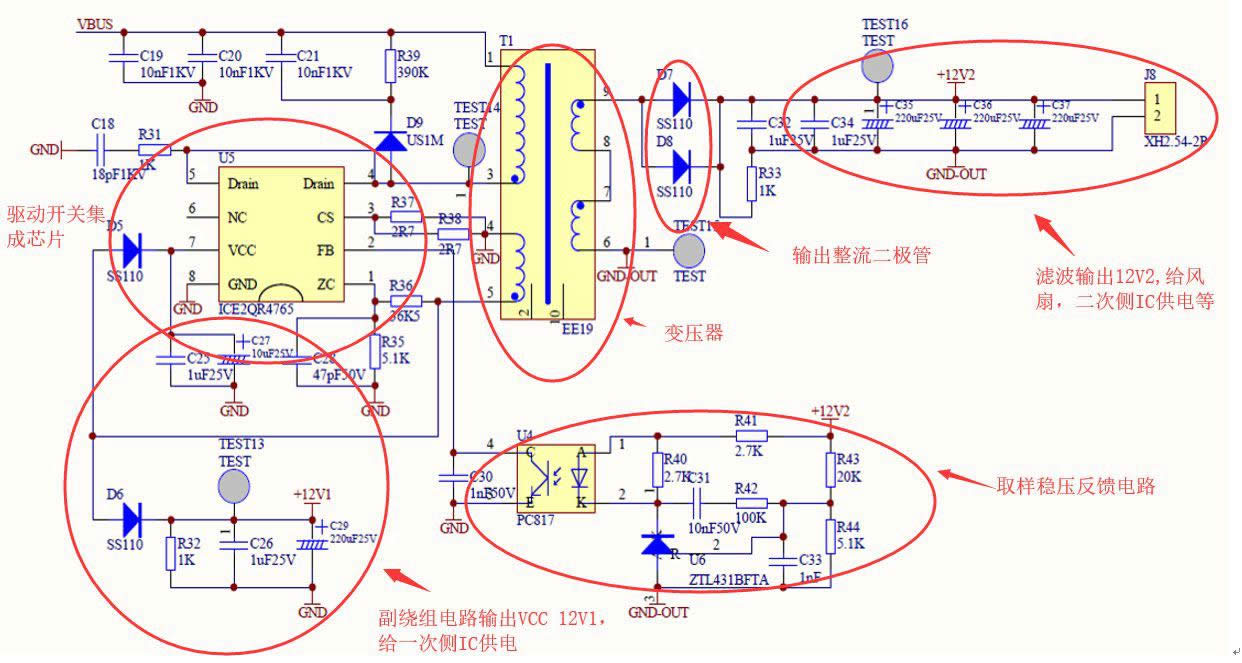

2.22 12V auxiliary circuit principle, if there is no 12V2 voltage and the fan does not rotate, focus on measuring whether voltage detection start chip U5 Pin 4 and 3 have short circuit, and whether resistor R37 and R38 change value and have open circuit, whether T1 (winding has open circuit), and whether fan Q5, D6, D9, D7, D8 are damaged. Voltage feedback check, etc.

驱动开关集成芯片: Drive switch integrated chip

变压器: Transformer

输出整流二极管: Output rectifier diode

副绕组电路输出 VCC 12V1,给一次侧 IC 供电: The secondary winding circuit outputs VCC 12V1 to supply power to the primary side IC.

取样稳压反馈电路: Sampling voltage feedback circuit

滤波输出 12V2,给风扇,二次侧 IC 供电等: Filter outputs 12V2, power supply for fan and secondary side IC, etc.

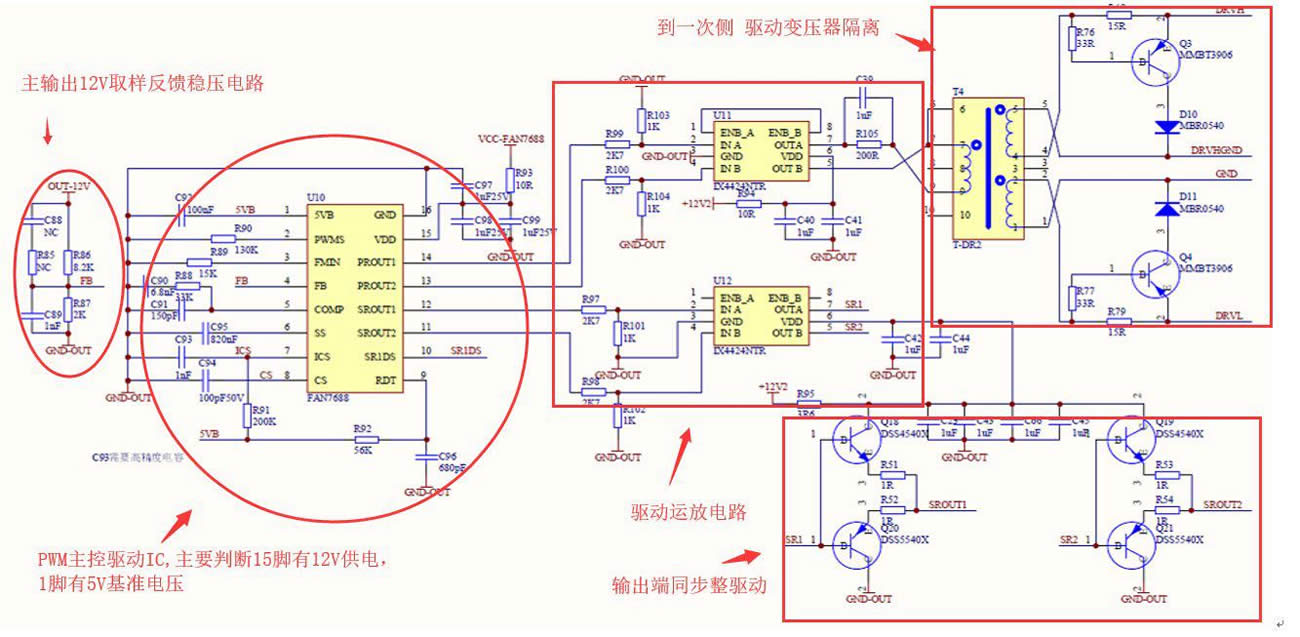

2.23 The schematic diagram of the main control PWM drive circuit, focus on measuring whether the main IC U10, VCC 12V power supply is normal, and U11, U12 and drive transformer T4 are damaged.

主输出12V取样反馈稳压电路: Main output 12V sampling feedback regulator circuit

PWM 主控驱动 IC,主要判断 15 脚有 12V 供电, 1 脚有 5V 基准电压: PWM main control driver IC, mainly judging whether pin 15 has 12V power supply, and pin 1 has 5V reference voltage.

到一次侧 驱动变压器隔离: To the primary side, drive transformer isolation

驱动运放电路: Drive op amp circuit

输出端同步整驱动: Output end synchronous drive

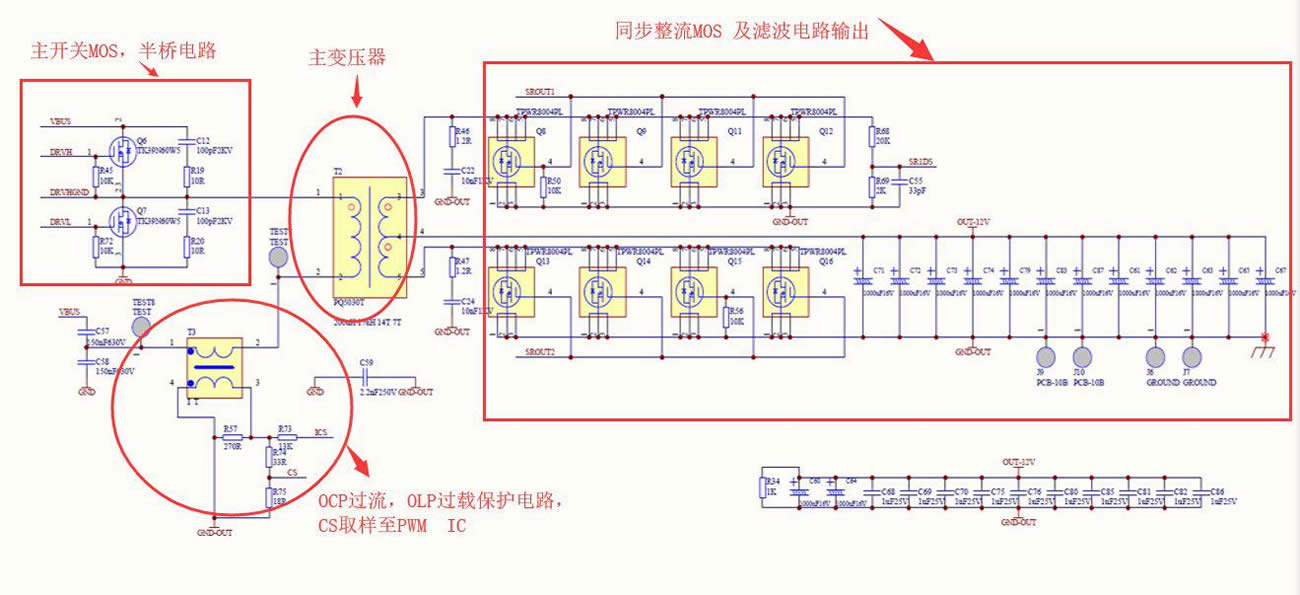

2.24 The main output circuit for the main switch MOS and transformer conversion buck synchronous rectification DC filter, focus on measuring whether the main switch MOS Q6, Q, output rectification terminal NMOS Q14; Q15; Q13; Q16, Q8, Q9, Q11, Q12 positive and negative poles have short circuit or damage.

主开关 MOS, 半桥电路: Main switch MOS, half-bridge circuit

主变压器:Main transformer

同步整流 MOS 及滤波电路输出: Synchronous rectification MOS and filter circuit output

OCP 过流,OLP 过载保护电路,CS 取样至 PWM IC: OCP overcurrent, OLP overload protection circuit, CS sampling to PWM IC

2.25 Location of A-side of SMD patch and B side of the plug-in

Figure 1 Side A of SMD patch

Figure 1 Side A of SMD patch

Figure 2 Side B of plug-in

Figure 2 Side B of plug-in

2.3 Maintenance steps

2.31. Check whether the appearance of the power supply is seriously damaged or deformed and whether the DC fan and the AC socket are damaged.

2.32. Power on AC 220V, check whether the fan is rotating normally, and use the multimeter to measure whether the output J6 terminal’s voltage is 12V (12.1V-12.50) to eliminate measuring error

2.33. Open the enclosure to check whether the components and solder surface have sparking phenomenon (focus on whether the R33 resistor is damaged), use a multimeter to detect whether the AC input terminal’s F1 fuse has an open circuit, whether the U2 rectifier bridge; PFC MOS Q1; D7; D5; D6 has a short circuit, whether the PWM circuit’s main switches MOS Q6; Q14; Q15; Q16 and output patches MOS Q17; Q18; Q19; Q20 have short circuit; if there is a short circuit, the component position should be checked and replaced, pay attention to the circuit resistance around bad bit MOS tube; the transistor may be damaged and needs to be replaced.

2.34. Detect whether the auxiliary 12V circuits U5; T1; Q5; D11 has a short circuit or open circuit and whether the surrounding components are burned, etc., replace if necessary.

2.35. If there is no abnormality in the above locations, the F1 fuse path is normal. After the AC is powered on, the DC fan rotates (if there is no rotation, check whether the fan socket has a voltage of 12V, if the voltage is normal, replace the fan); the output terminal J6 has 12V voltage, measure whether it is DC370V-380V at both ends of PFC large capacitor C16 or C17, otherwise check whether U1, pin 7V VCC power supply has 12V or judge material damage and replace, if there is no abnormality, it needs to detect PWM circuit U9; U10; U11; whether supply VCC has 12V voltage or judge material damage and replace, and whether the T4 drive transformer is damaged.

2.36 Other bad needs to be further analyzed and judged according to the skills of maintenance personnel.

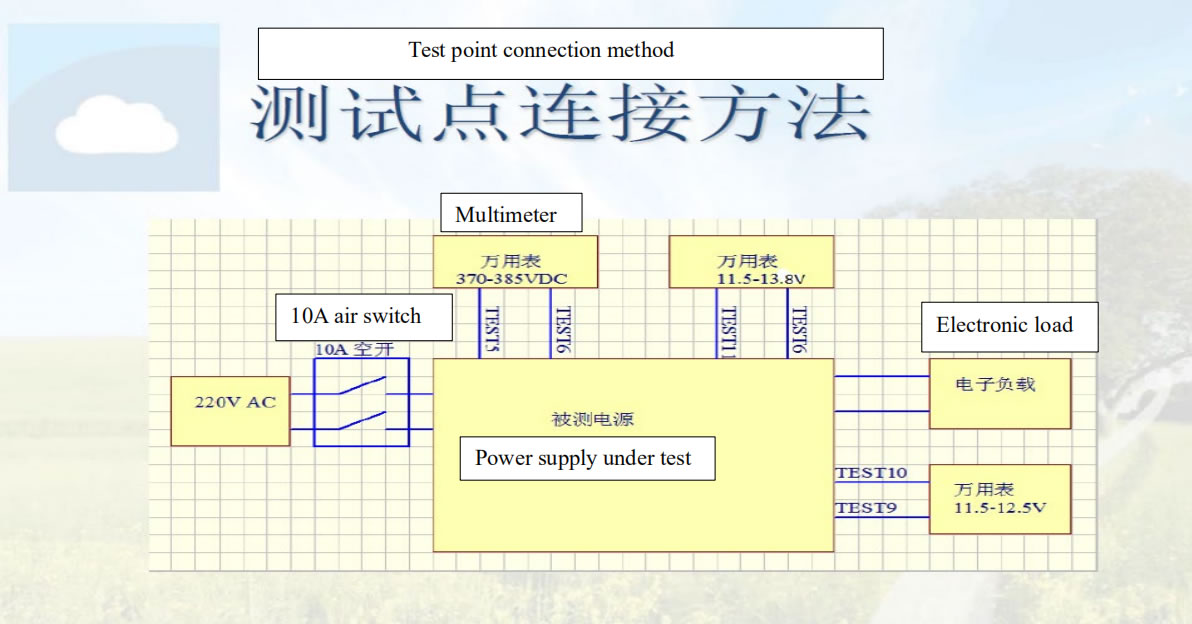

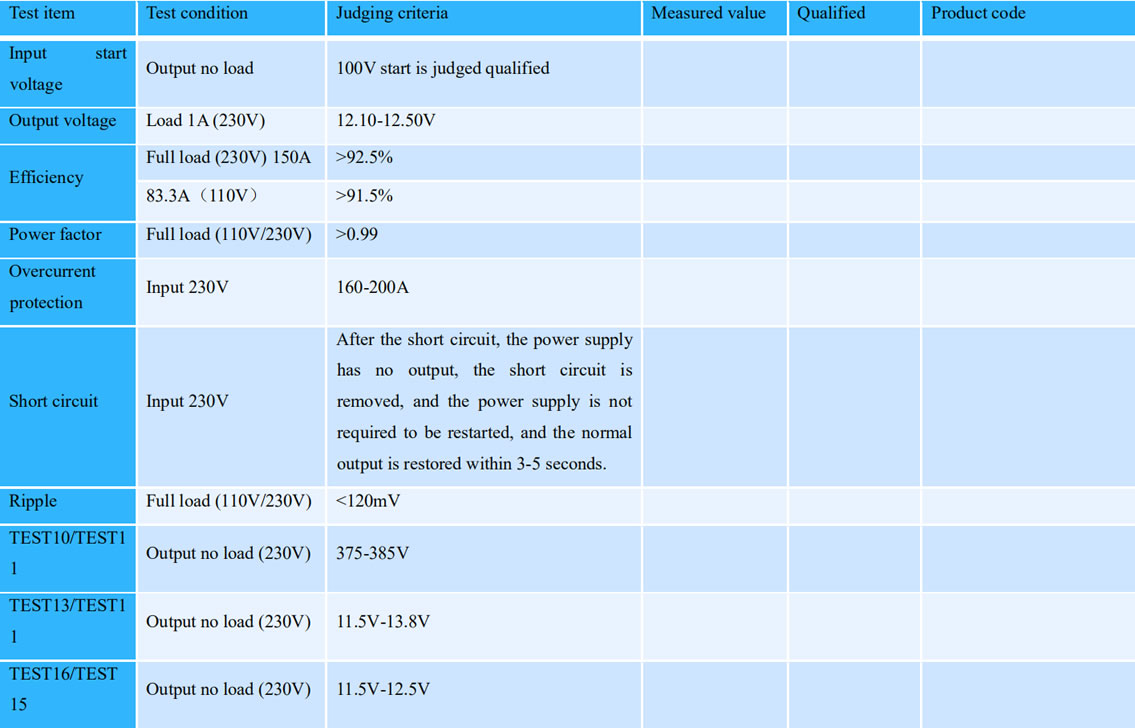

2.4 Diagram for electrical function test connection, PCBA main voltage measurement point.

Test steps:

(1) Visually inspect the board. Make sure that the board has no pseudo soldering, continuous soldering, electrolytic capacitor polarity, plug-in components are installed in place, MOS tube insulation gaskets are normal, and then connect the board input line L/N and the output line’s positive and negative poles.

(2) Turn on the AC input’s air switch. After all the multimeters are correctly read (the judgment condition is in the above figure), set the electronic load current to 1A, and record the electronic load voltage at this time as the load voltage, the voltage value is qualified between 12.10-12.50V.

(3) Input 220V, set the electronic load current to 150A, record the voltage, power and power factor of the AC side power meter. If the power factor is greater than 0.99, the output voltage is normal, and the power is not less than 1800W, it is qualified. Rotate the electronic load knob to increase the current by 2A/div. If the current protection point is directly protected at 160-200A, it is qualified, and the protection value is recorded. Set the short circuit protection. After the power is turned back on, the power supply can operate normally.

(4) Input 110V, set the electronic load current to 83.3A, record the voltage, power and power factor of the AC side power meter. If the power factor is greater than 0.99, the output voltage is normal, and the power is not less than 1000W, it is qualified.

(5) Turn off the AC switch and electronic load in turn, and remove the AC input line and DC output line. Note: The large electrolytic capacitor is charged before the fan stops. You need to wait until the fan stops completely before you can touch the board.

Judging criteria (this test requires electronic load, power meter, voltage regulator)

Remarks: After the maintenance of the power supply, if the above items have no equipment conditions, it only needs to test the input AC 220V, output 12V plus load 150A (1800W), it can work normally, it is also considered qualified.

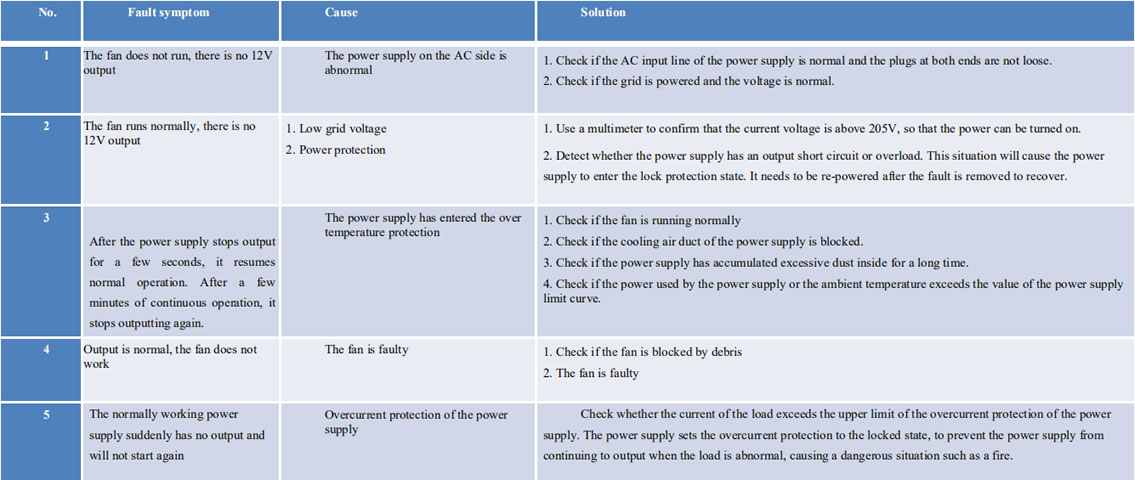

2.5 Simple judgment and maintenance of common faults of mine power supply

2.6 After the power supply maintenance test is normal, it is required to operate normally for 2 hours with a rated load of 80% (130A) or more before it can be used by the client.

عملاؤنا الكرام:

عملاؤنا الكرام، نظرًا لقرب حلول عطلة رأس السنة الصينية، سيتم تعليق خدمات الشحن الدولي. ستتوقف شركة زيوس للتعدين عن الشحن اعتبارًا من 11 فبراير 2026. وستمتد عطلة رأس السنة الصينية من 12 إلى 23 فبراير 2026 (بتوقيت غرينتش +8). ستُستأنف خدمات ما قبل البيع وما بعد البيع في 24 فبراير 2026، وستُستأنف عمليات الشحن في 24 فبراير 2026. نشكركم على دعمكم وثقتكم بنا في عام 2025. في عام 2026 وما بعده، سنبذل قصارى جهدنا لتقديم منتجات وخدمات أفضل لكم.

مع خالص التقدير،

ZEUS MINING CO., LTD.